Activated Carbon for Pharma Industry: Uses, Grades and Quality Standards

If you are in the pharm sector, you already understand the urgency of meeting several compliance standards. And a great deal goes to maintaining the purity and legitimacy of your products, doesn’t it? It starts from the elimination of impurities to maintaining color through critical procedures and testing.

As you navigate the stringent regulatory demands, opting for the correct pharma-grade activated carbon (AC) ensures compliance and integrity of your products. Our experts at Austro Carbon understand what it takes to ace the product development from synthesis to final formulations. But don’t worry, as in this blog we will unlock some key insights on how activated carbon for pharma industry is crucial; that will give you an edge over others. As you navigate, you will understand how elevating your filtration and purification game can impact your batch yields and market readiness.

Why Activated Carbon Is Used in the Pharmaceutical Industry

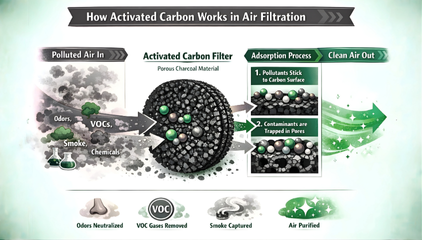

Activated Carbon’s extensive capacity for adsorbing organic impurities, residual solvents, and color bodies, which other systems cannot effectively address, is the primary reason why industrialists opt for AC as their purification medium.

With a very high surface area property (in excess of 1000 m²/g), AC can effectively adsorb a wide variety of contaminants selectively, so that you can provide a higher purity and longer shelf-life for your products without affecting the active ingredients. Moreover, it can easily integrate into and work well with pharmaceutical manufacturing processes, whether by using it in batch reactors, filtration units, or in columns. With AC as your purification medium, you are able to purify stable compounds (i.e., heat-sensitive) and aqueous solutions, and at the same time preserve the quality and efficacy of the compounds you are processing.

Key Uses of Activated Carbon in Pharma Industry

Now that you know about the potential of AC in pharma, which is due to its adsorption capability, you have to have a thorough understanding of its applications as well. Did you know that Activated Carbon is added to tablets and capsules for the treatment of gastrointestinal issues and hangovers? Well, that was just some quick information. Here’s a detailed list of applications:

- API Purification and Intermediate Processing: Pharma manufacturers use it to polish active pharmaceutical ingredients (APIs), stripping away trace impurities that could compromise bioavailability or safety.

- Decolorization of Pharmaceutical Solutions: For injectables or oral liquids, it removes unwanted hues from raw materials, ensuring your products meet visual standards.

- Solvent Purification and Recovery: In extraction processes, experts recover and reuse solvents like ethanol or acetone, cutting costs while meeting environmental regs.

- Antibiotic and Bulk Drug Manufacturing: It targets fermentation broth impurities in penicillin or cephalosporin production, boosting yield and potency.

- Activated Carbon as a Processing Aid: Pharma professionals add it temporarily to stabilize intermediates, then filter it out, preventing microbial growth or oxidation.

The above-mentioned activated carbon uses in pharmaceutical industry indicate that there is no other alternative to the same. With its affordability and efficiency, it has proved its worth in every quality aspect of this sector.

Grades of Activated Carbon Used in Pharmaceutical Applications

Now there are different grades of AC depending on the sources (wood, coconut, coal), activation method (like chemical or steam), and forms, which are given below for your prompt understanding

- Powdered Activated Carbon (PAC) for Pharma: Fine particles (10-50 microns) excel in batch decolorization and API polishing, offering rapid adsorption for your high-volume runs.

- Granular Activated Carbon (GAC) for Pharma: Larger granules (0.5-4 mm) suit column filtration and continuous solvent recovery, providing longer bed life and easier handling.

- Impregnated or Modified Activated Carbon: Customized with silver or acid washes, these target specific contaminants like mercury or odors, enhancing your specialized formulations.

So, before you invest a great deal in your activated carbon procurement, try to gain a deep knowledge of the same. If you are stuck on this homework, feel free to reach out to our team at Austro Carbon. With our extensive experience in this sector, we believe a thorough consultation is the bare minimum for your satisfaction.

Pharmaceutical Grade Activated Carbon – Quality Standards

Not every grade of AC gels perfectly with the type of requirement in the pharma industry. Generally, it asks for international standards like BIS, ASTM, EU, EP, AARL, and others. Reliable exporters like us would follow GMP protocols, which ensure zero cross-contamination. Here are some key parameters which you should check beforehand

- Surface area and iodine number for adsorption capacity.

- Moisture content (<5%) and particle size uniformity.

- Microbial limits and loss on drying, verified via independent labs.

Once you conduct the due diligence online and cross-check via product reviews, you can proceed without any second thoughts.

How to Select the Right Activated Carbon for Pharma Industry

The first step when selecting a carbon-grade product is to identify which carbon-grade to use for your application. For quick batch processing, typically PAC is utilized, while for full-scale, continuous flow-through processes, GAC is the product of choice to achieve optimal results.

When selecting one of these two products, evaluate how much methylene blue has to be adsorbed versus the cost of each product. Using an economical and reliable manufacturer allows you to reduce the total carbon dosage required for your application and will also allow you to stay within your budget limits for the overall project.

Supplier reliability should be the next priority. Ideally, find a certified supplier with good reviews on the internet.

Benefits of Using High-Quality Activated Carbon in Pharma

High-quality activated carbon transforms your operations. You achieve superior product purity, meeting assay specs and extending shelf life. Subsequently, regulatory compliance becomes effortless, passing FDA or EMA scrutiny easily.

Process efficiency rises with faster purification cycles and solvent recycling, slashing waste by up to 30%. Best of all, it minimizes batch failures from impurities, protecting your margins and reputation.

Conclusion

There is no doubt that activated carbon for pharma industry forms an integral part of its toolkit. From API synthesis to final refinement, you have to have the right AC in place. Moreover, matching the current industry standards of the sophisticated pharma market is heavy. Thus, conducting a thorough due-diligence before purchasing is a must.

If you are still confused about which grades to go for your pharma purification needs, or just not sure about where to start, we are all ears.