Activated Carbon for Mercury Removal: Complete Industrial Applications Overview

Elimination of mercury in most industrial processes is a big deal, even in 2025. The environmental compliance related to these operations is of high importance. It’s considered to be a toxic pollutant that can significantly impact the health of the workers and the overall ecosystem if not controlled flawlessly. And the best way to eliminate the same is through the application of activated carbon (AC).

Through this blog, our experts at Austro Carbons will guide you through the processes of mercury removal with Activated Carbon. It will also give you detailed insights into some significant industrial applications so that you can align with your industry. Overall, it will help you understand why you should go for the best AC in your mercury removal operations.

What is Mercury Removal & Why Industries Need It

Mercury pollution is undoubtedly one of the hazardous pollutants out there, discharged through industrial emissions and wastewater. The source of the same is from diverse industrial activities such as waste incineration, coal combustion, gas processing, and chemical production. Once mercury is deployed in the environment, it can contaminate water, air, and soil, posing substantial health risks, including developmental and neurological consequences.

Global environmental standards have levelled up, with rising global warming. This is very concerning for industries like yours to meet the same. The reason being- many industries in India are already finding it challenging, thus facing huge idle times, and even shutdowns. Thus, mercury removal isn’t just good for our environment, but also for you to run a sustainable operation. We also understand your budget point of view. And the good news is that the best cost-effective mercury removal can be done through the implementation of activated carbon. It is a solution that is the need of the hour- affordable and efficient.

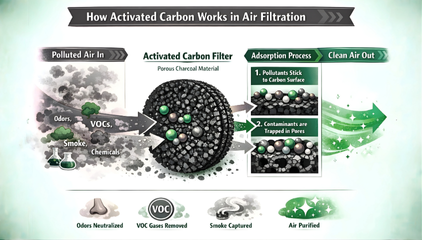

Why Activated Carbon is Used for Mercury Control

Activated carbon’s potential in mercury removal is so effective that it is getting recognized as the ideal one in several parts of the country and across diverse industries. Its physical attributes make it flawless for mercury adsorption. It has the optimum surface area to trap and hold mercury particles effectively. This unique property makes AC incredibly versatile, appropriate for treating both flue gases and wastewater.

Also, as mentioned earlier, its affordability and user-friendliness make it more versatile. You don’t need to overhaul your existing systems. It blends seamlessly with standard industrial processes. Over the last few years, several success stories have come up from diverse industries. This means when you embrace AC in your mercury removal process, you rely on tried-and-tested methods optimized for your industry needs.

Major Industrial Applications

Let’s decode how AC is getting embraced in different industry setups, particularly in flue gas treatment and wastewater recovery.

- Flue Gas Treatment

If your industrial operations involve burning coal or waste, the emissions are likely to be mercury-borne. In a normal setup, manufacturing plants such as cement production or coal-fired power plants release mercury into the air. In these cases, mercury removal from flue gas becomes crucial. When activated carbon injections (ACI) are implemented, they capture (adsorb) mercury vapour from flue gases efficiently. This significantly minimizes the amount of toxic emissions your plant releases.

Subsequently, the overall result due to the implications of powdered AC injection is noteworthy. It ensures that your plant complies with environmental laws and safeguards local communities.

- LNG Processing

As a matter of fact, mercury is present in almost all natural gas fields in concentrations from <10 ppb to >1 ppm as metallic, inorganic, and organic compounds. And if industries fail to identify non-detectable levels, it can poison catalysts used in downstream process units and eventually damage expensive aluminium cryogenic equipment used in liquefaction.

To prevent costly downtime and equipment failure, you need to conduct LNG mercury removal before the gas reaches this stage. Granular activated carbon (GAC) beds provide a robust filtration solution that adsorbs mercury from the gas stream. This ensures your LNG processing is safer, more efficient, and aligns with industry quality standards.

Types of Activated Carbon Used in Mercury Removal

Opting for the appropriate form of AC is key to maximizing mercury removal efficiency for your specific process.

- Powdered Activated Carbon (PAC): This fine powder is ideal for flue gas mercury control. You can inject it directly into your emission control systems, where it binds mercury vapors quickly.

- Granular Activated Carbon (GAC): With its larger size, GAC works well in fixed-bed filters for gas purification applications such as LNG processing. It’s easier to handle for continuous filtration setups.

- Impregnated Activated Carbon or Modified Ones: These types are treated with chemicals that enhance their mercury affinity, offering robust bonding and higher removal capacity. Consider this if you need to meet especially tough emission targets or have high mercury concentrations.

Key Benefits for Industries

When you implement activated carbon for mercury removal, you gain several advantages that impact your bottom line and operational success.

- High removal efficiency: AC offers exceptional mercury capture, often exceeding regulatory requirements.

- Subtle installation and operation effort: It can be integrated into your existing systems with minimal adjustments, reducing downtime and labor.

- Cost-effective solution: Compared to other methodologies such as MoS2 or catalytic oxidation, AC delivers excellent performance at an affordable range.

- Regulatory compliance: Using activated carbon helps you meet strict environmental standards and avoid penalties.

- Versatility: Works across various industries and process types, whether treating gas streams or wastewater.

Why Choose High-Quality Activated Carbon

Not all activated carbon products are created equal. To get the best results for mercury removal in your facility, you should source high-quality AC that has the optimum parameters in place. For instance, surface area, pore size, moisture content, bulk density, and thermal density are some of the few important parameters that you should cross-check before investing.

Additionally, using a product tailored to your industry and setup ensures safe handling and reliable mercury capture. This adds to your process’s overall safety and boosts your confidence in meeting compliance goals.

Conclusion

A random industrial activated carbon supplier can be producing different qualities and forms of activated carbon in the market. One never knows for sure. And for you, as a decision maker of a sustainable industrial plant, you need to understand what’s best for your industrial processes. Ultimately, it all boils down to getting a high-quality activated carbon that will meet the stringent government compliance.

If you are still not sure which one to go for, you can reach out to our expert team at Austro Carbon. Since we are one of the pioneers in this domain, our products meet international quality standards such as ASTM, AARL, BIS, and EU. Bring the best activated carbon to your plant today, so that you can lead a healthy ecosystem tomorrow.