Activated Carbon For Water Treatment: Types, Mechanism, Applications & Advantages

Activated carbon use in water treatment is nothing new. For decades, well before modern filtration systems were invented, it had been in use. Early civilizations used charcoal in water jars and simple methods of filtration to clean drinking water and also to improve taste and odour.

Today, activated carbon is also used for wastewater treatment in households and industries, though its usage has changed significantly over the years. Activated carbon is offered in different grades and is fashioned to cater to every industrial demand. Municipalities need a different kind of activated carbon when it comes to the treatment of wastewater, which again is not used in industries like gold recovery.

Wastewater can be effectively treated in a timely and almost economical manner by selecting appropriate quality-ensured international-standard activated carbon. The ultimate result is cleaner and safer water, fit for reusage or consumption.

At Austro Carbon, we are committed to providing the best quality activated carbon for water purification. Having been in this industry for more than 13 years, we try to bring to you practical insights through this blog, which will further help you understand activated carbon and its role in water treatment.

Types & Grades of Activated Carbon for Water Treatment

In the market, there are different grades of AC, which are classified in terms of their source material and texture. Here’s a quick overview of the types of activated carbon for water purification:

- Wood-based carbon: delivers a wider pore distribution, suitable for decolorization and treating larger organic molecules.

- Coal-based carbon: provides high mechanical strength and longevity, making it ideal for industrial filtration systems

- Coconut shell-based carbon: offers high density and micro porosity, perfect for eliminating low-molecular-weight organic compounds and improving taste.

On the basis of form, Granular Activated Carbon (GAC) is the go-to AC for perpetual flow systems and column filters. On the other hand, Powdered Activated Carbon (PAC) is utilized for faster treatment in batch processes or as an additive in water treatment plants.

Based on your application, you can also opt for high-purity grades that meet stringent international standards like ASTM, AARL, BIS, and EU, or standard grades for general-purpose water purification.

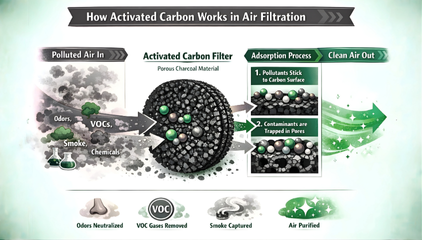

How Activated Carbon Works in Water Treatment

“Adsorption” is the feature that makes activated carbon the best filter material out there. The texture of activated carbon is highly porous, which traps the contaminants with accuracy and ease. In other words, it holds onto molecules on its surface, effectively capturing unwanted impurities and chemicals.

This adsorption water treatment method is based on two parameters of AC: its pore size and surface area. The ratio goes as: the greater the surface area, the greater is the room for adsorption. Micropores target tiny organic molecules, while on the contrary, mesopores handle bigger compounds.

Activated carbon not only helps in removing chlorine from water but also chloramines and organic compounds. In fact, all of which affects the water’s taste, odor, and safety. This mechanism also safeguards downstream membranes from degradation in advanced treatment systems.

Contaminants Removed by Activated Carbon

Activated carbon is capable of TOC reduction water, but that is not its sole capability. Here’s a gist of substances that it can eliminate seamlessly:

- Chlorine and chloramines.

- Natural organic compounds and disinfection by-products.

- Volatile Organic Compounds (VOCs) such as benzene and toluene.

- Emerging contaminants like PFAS, pharmaceuticals, and personal care residues.

This extensive removal capacity ensures that your treated water remains safe, clear, and free from harmful chemicals and unpleasant tastes. And if you are running a business related to the FMCG sector, then rest assured, you will get the best water quality down the line. Talking of AC usage in industrial sectors, read the next section to know more.

Applications of Activated Carbon in Water Treatment

If you are in the FMCG sector or any other sector, seeking a reliable material for water treatment, then AC should be your go-to material. It not only provides consistent water quality but also comes cheaply as compared to other methods of filtration. Here is a brief outline of its applications:

- Food & Beverage Industries

- Boiler feed water and cooling towers

- Hospitality and commercial use

- Drinking water filtration systems

- Municipal water treatment

- Industrial wastewater treatment

- Laboratory and pharma applications

- Aquarium and pool filtration purpose

Advantages of Using Activated Carbon for Water Treatment

When you incorporate activated carbon into your water treatment process, you gain multiple advantages:

- Recognizable improvement in water quality in no time.

- Optimizing Total Organic Carbon (TOC) levels, thus dominating the effect of bad substances.

- Ultimate safeguarding of the membrane in reverse osmosis and ultrafiltration systems.

- Proves to be a more cost-effective solution as compared to other methods of filtration, such as UV treatment or biological degradation.

Selection Guide

Identifying the correct activated carbon depends on your system’s design and treatment objectives. Here are some vital factors to consider:

- Based on the contaminant profile, opt for the appropriate grade and source type (wood, coconut, or coal). It should match the correct activated carbon specifications.

- Evaluate volume needs and lifespan to ensure consistent performance without overuse.

- Think about the chances of regeneration. Your AC should be sustainable in the long run, especially if you are running a business.

- Optimize the cost and quality trade-off: sometimes, investing in premium grades yields longer-term savings due to higher adsorption capacity.

Maintenance & Troubleshooting

Just like any other filtration system, AC filtration systems need proper maintenance too. But when done periodically, it’s not a hassle. Here’s what you can do:

- Go for cartridge replacement or carbon bed reactivation once adsorption sites become saturated. The threshold is typically detected in terms of alteration in water taste or chlorine levels.

- Keep an eye out for bacterial growth. It’s a common headache in stagnant areas. Periodic sanitization and backwashing can prevent the same.

- In case of bulk requirements, consider thermal or steam regeneration to reinstate adsorption capacity and extend the carbon’s life cycle.

By abiding by proper activated carbon filter maintenance, you will not only increase its lifespan but also get consistent water quality.

Sustainability & Lifecycle

Yes, activated carbon is already considered a sustainable filtration practice since it’s derived from organic materials. But if you can add to its recyclability or such practices, it would contribute a lot of positive outcomes to the environment.

Appropriate reutilization of used carbon prevents passive pollution and complies with regulatory needs. So, collaborating with a responsible supplier ensures that every stage of your carbon lifecycle remains environmentally sound. You can reach us at Austro Carbon if your business is looking for activated carbon suppliers who respect sustainable practices.

Conclusion

AC is undoubtedly the best practical solution when it comes to water purification solutions, even today! Whether it’s for municipal, domestic, or industrial wastewater treatment, no other alternative can do that level of filtration at that price point.

So, if you are seeking top-notch Activated Carbon that meets international quality standards like ASTM, BIS, EU, Austro Carbon is there for you. Since 2011, we have started our activated carbon legacy at Thoothukudi, Tamil Nadu, for clients across India and beyond.

Reach out today to learn more about how our advanced grades of activated carbon can optimize your water treatment process. Moreover, our prompt delivery services won’t add to your idle time.