How Activated Carbon Works in Air Filtration: Mechanism, Applications & Advantages

Humanity is keeping a keen eye on the air quality of its respective countries. The rise of air pollution, especially in Asian countries, has affected a significant demographic. From Nepal to Egypt and India, this topic is a matter of concern. This is because living in poor air quality affects your overall health and reduces your lifetime span. This, in turn, is making governments bring in stringent filtration standards for industrial processes. And that is where the role of Activated Carbon (AC) comes into the picture.

Our experts at Austro Carbons have come up with this blog as a guide to help you understand how AC powers air filtration. For your better comprehension, this involves real-world applications and key benefits. So, read each section if you want to decide the right filtration solution for your respective home/industry.

What is Activated Carbon?

Activated carbon (AC) happens to be a highly porous substance. It is engineered to capture contaminants from air and water through the process of adsorption. Genuine manufacturers like us at Austro Carbon produce it through a process where raw materials undergo carbonization (heating in low oxygen). This is followed by activation, which makes the resulting material exposed to steam or chemicals. This help forms millions of micropores.

As a matter of fact, it comes in forms tailored to your needs:

- Granular Activated Carbon (GAC) for air filters and columns, extruded or pelletized for uniform flow, and

- Powdered Activated Carbon (PAC) for fine dispersions.

Its uniqueness comes from its unmatched properties. It has a surface area up to 3000 m² per gram, substantial porosity, and noteworthy adsorption capacity. Moreover, you have a plethora of raw materials to choose from, based on your preferences. For instance-

- Opt for coconut shells for top-quality and sustainable solutions (it’s a must if your brand abides by eco-friendly practices)

- Another eco-friendly material keeping carbon footprint in check is bamboo

- Coal for durability

- Opt for wood if you have a tight budget

Being a pioneer in this field since 2011, we at Austro Carbon, we craft these products from powdered to granular, meeting global standards like ASTM, AARL, BIS, and EU directives. So, you can rely on us for your end-to-end air filtration needs.

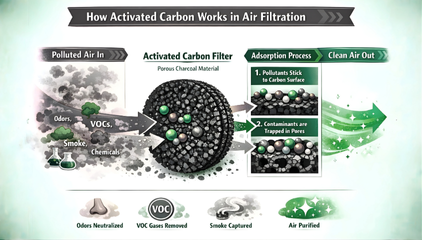

How Activated Carbon Works in Air Filtration

To understand the whole methodology of AC filters, you need to comprehend certain aspects and terminologies at first. Read the next three sections offering a holistic insight into how activated carbon works:

- Adsorption vs Absorption

You might confuse adsorption with absorption, but they’re worlds apart. The absorption process in air filtration soaks substances into a material’s bulk, like a sponge with water. Adsorption, however, clings pollutants to the surface, like dust on a magnet. Activated carbon shines here, binding gases and odors onto its vast pore walls without letting them escape.

- Relative Mechanism

To comprehend the carbon filter mechanism, picture air flowing through your filter: contaminants meet the carbon’s surface and get trapped via physical adsorption, powered by weak Van der Waals forces that attract molecules into pores. For trickier foes like acid gases (e.g., H₂S or SO₂), chemical adsorption kicks in, where surface functional groups form stronger bonds.

Pore size distribution is your secret weapon. Micropores (under 2 nm) trap minute VOCs, mesopores (2-50 nm) grab larger odors, and macropores channel airflow. Due to this multi-layered process, you get a meticulous capture mechanism that regenerates partially as minimal molecules desorb over time.

- Factors Affecting Performance

Your filter’s efficiency hinges on conditions. High temperatures speed desorption, reducing capacity, while optimal humidity (below 60%) prevents water competition. Airflow rate matters too. It goes beyond the required rate, and molecules zip by; too slow, and resistance builds.

Opt for the right form: granular for low-pressure drops in HVAC, pelletized for steady industrial flows, or powdered for compact residential units. With Austro Carbon’s tailored products, you fine-tune these factors for peak performance.

Applications of Activated Carbon Air Filters

In your home, activated carbon tackles everyday nuisances. Get rid of VOCs from paints and cleaners, cooking odors, cigarette smoke, and pet smells. You and your family breathe fresh air in any kind of in-house situation.

If you run an industrial factory setup that deals with harmful chemical processes or waste treatments, then you can incorporate AC filters to neutralize chemical gases, solvent vapors from printing and painting, and other emissions. Factories using high-quality GAC from manufacturers like ours cut downtime and comply with regulations effortlessly.

Hit the road, and it purifies automotive cabins, controlling exhaust fumes and new-car odors in your vehicle’s filter. Public transport benefits too, reducing passenger complaints. Premium carbon, like Austro Carbon’s EU-compliant grades, excels in hospitals (sterilizing air) or airports (odor control), and makes the environment pollutant-free.

Advantages of Using Activated Carbon in Air Filtration

There are numerous benefits in using activated carbon for air filtration in different setups. You gain unbeatable effectiveness against gases and odors that HEPA filters ignore. You can expect more than 99% removal of VOCs and H₂S. It’s non-toxic, safe for your lungs and the planet, with natural raw materials breaking down harmlessly.

Pair it with HEPA for hybrid power: carbon handles gases, HEPA grabs particles, delivering hospital-grade air in your space.

With quality activated carbon filters, you enjoy longevity. Your filters last 6-12 months in homes, years in the industry, with steam or thermal regeneration options, slashing replacement costs. Low pressure drop means energy savings, and versatility blends with any system. From ductless minis to massive scrubbers, you’ll get an AC air filter appropriate for your needs.

Conclusion

If you have decided to go for an activated carbon air filtration system, then you are on the right track. It’s the best cost-effective solution as of today. But you have to ensure that you incorporate the best activated carbon filter system out there in the market.

If you have yet to identify a reputable activated carbon manufacturer that caters to air filtration equipment, then reach out to us today. Our experts will help you out so that your purpose doesn’t fail on the first attempt.

FAQs

No. HEPA filters combined with activated carbon and captures dust particles

An activated carbon filter generally lasts for around 3 to 12 months, depending on your usage, air quality, and other external factors.

Yes, and it’s very effective. The level of impact depends on carbon quality, amount, and pollutant concentration. Still, you can expect around 50% in a matter of time.

Activated carbon is charcoal processed through activation (steam or chemicals) to create vast micropores and a high surface area (800-2000 m²/g) for superior gas adsorption in air filters.

Regular charcoal lacks this activation, offering lower porosity (10-100 m²/g) and minimal filtration beyond basic odor control.